The online quenching device for aluminum profiles

An important equipment used to quickly cool down the high temperature aluminum profiles after extrusion

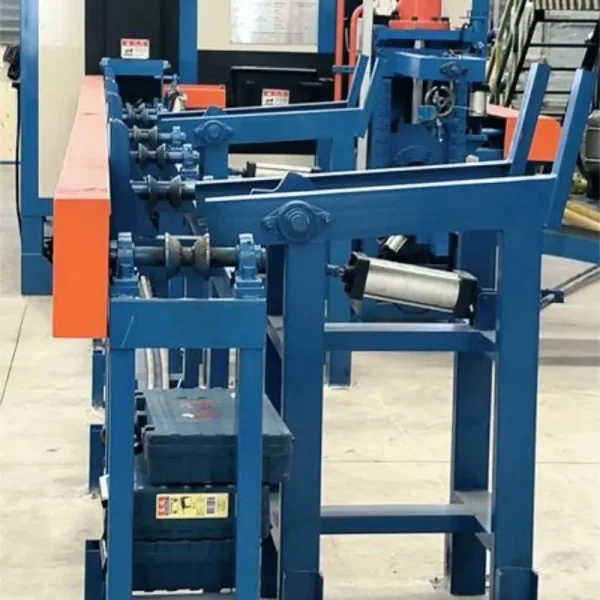

Aluminum profile air cooling equipment is mainly composed of the following parts:

- Fan system: including fans, motors, fan blades and other components, responsible for generating and controlling the flow of air, is the key to the cooling effect.

Air duct design: The air duct is divided into upper and lower air ducts, the fan is evenly distributed, and the design of dislocation blowing can ensure that the air is evenly and stably blown to the surface of the aluminum profile, improving the cooling efficiency. Air ducts may be equipped with air deflectors, diffusers and other devices to optimize airflow distribution.

- Control system: used to control the operation of the fan system, including the adjustment of wind speed and air volume. The on-line quenching device is equipped with an intelligent control system, which can automatically adjust the cooling parameters according to the temperature, specifications and other parameters of the aluminum profile to achieve the best cooling effect.

- Conveying system: used to transport extruded aluminum profiles from the extrusion press to the wind cooling equipment, and move and position inside the equipment. The conveying system usually adopts chain, roller or step structure to ensure the stability and accuracy of the aluminum profile in the conveying process.

- Efficient cooling:Through the powerful fan system and optimized air duct design, the aluminum profile wind cooling equipment can quickly reduce the temperature of the aluminum profile and improve production efficiency.

- Uniform cooling: Reasonable air distribution and delivery system design can ensure that aluminum profiles are heated evenly during the cooling process to avoid local overheating or undercooling.

- Energy saving and environmental protection: compared with other cooling methods (such as water cooling), wind cooling equipment does not need to use cooling media (such as water), so it has the advantages of energy saving and environmental protection. At the same time, the wind cooling equipment is less noisy during operation and has less impact on the environment.

- Easy maintenance: The structure of aluminum air cooling equipment is relatively simple, and it is more convenient to maintain. At the same time, the components inside the equipment (such as fans, motors, etc.) have high reliability and durability, which can reduce maintenance costs.