The aging furnace consists of five parts: furnace body, chain traction and conveying system, hot air circulation system, energy-saving heating system and electrical control.

The furnace body is welded by high-strength steel, and the furnace is closed by front and back doors, forming a space for heat exchange between hot air and aluminum profiles.

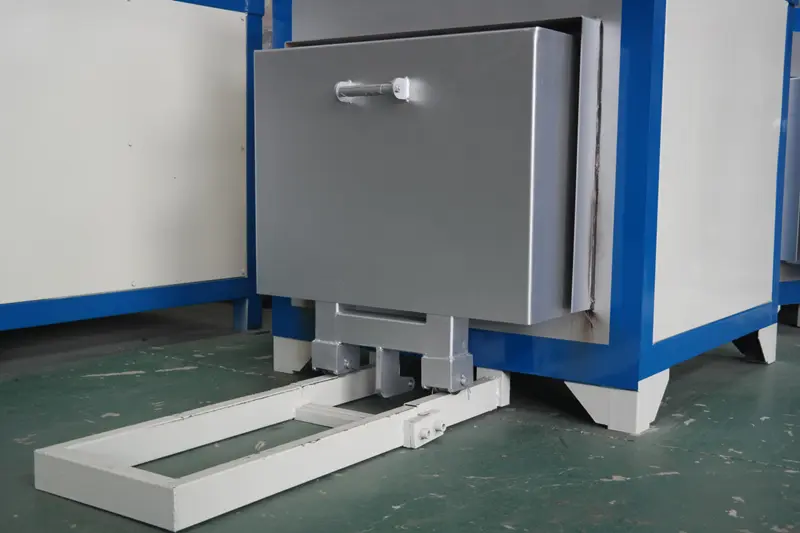

The inner and outer support frames of the furnace body are welded by square tubes to ensure that the furnace body has sufficient strength and good airtightness, and can adapt to the thermal change of the steel plate at normal temperature to 350 DEG C; the inner side of the side wall of the furnace body adopts Grade A compressed glass fiber silicate cotton; the furnace door adopts a guide rail design; the furnace door is sealed by four air cylinders; and is protected by a safety bolt after the furnace door rises to the top to prevent the furnace door from falling itself. The sealing groove is installed on the furnace door to ensure that hot air does not leak out during heating. The lifting of the furnace door is driven by a motor, supplemented by a counterbalance weight, which increases the service life of the motor and makes the lifting transmission easier.

Natural Gas Heating (Energy Saving)

The heating gas combustion gun is equipped with a frequency converter and a proportional valve method, which makes the temperature control more intelligent and accurate. It automatically sweeps the air before ignition to ensure safe and reliable combustion. The heated air is sent to the air outlet on the furnace door by the circulating fan, and passes through the air outlet. Sprayed to the product to be heated in layers. The temperature in the furnace is measured by thermocouples reasonably distributed in front and behind the fireside, and the firepower is controlled.

Description of the process

When the aluminum alloy profile is extruded out, straightened and cut to length, it must be loaded into the aging furnace for aging treatment. The aging furnace can handle profiles with different lengths. Before the profiles are put into the furnace, they must be loaded into a material frame, and then stacked according to the section. After the stacking, the material frame is filled on the special discharge roller table for feeding and discharging materials, the furnace door pressing mechanism is pneumatically released, the furnace door is electrically raised, the reducer is started to send the material frame into the furnace, the circulation fan is started, and after the operation is normal, the liquefied petroleum gas heating system is started to heat up, and the furnace door is pneumatically pressed, and the furnace door is finally pneumatically.

After the temperature is raised to the process temperature (generally 185 °C), the temperature is constant for a period of time (according to the time set by the process), then the heating is stopped, the fan is stopped, the furnace door pressing mechanism is pneumatically released, the furnace door is electrically raised, the discharge trolley is discharged, and the material frame is driven out of the furnace, and the profile is cooled for later use.

- Application scope, function achievement, and description of quality indicators

- Application scope: in line with the supporting use of the front extrusion production line;

- Function: Use the fan to do hot air circulation treatment. The furnace door is opened, and the material feed and discharge design is carried out by using the ground rail operation; The hot air circulation system adopts a multi-wing fan to ensure a minimal temperature difference in the furnace. The heating system adopts natural gas burner for heating, and the combustion of the burner is controlled by PID proportion, which ensures complete combustion and uniform furnace temperature. The cooling system is air-cooled

- Description of achieving quality indicators:Meet the aging requirements of the extruded products of the front extruder. After the aging furnace normally reaches the aging temperature of a certain type of material, it can be kept in a heat preservation state for 2-24h (the aging time depends on the process requirements of the profile)

Equipment structure

The 80×40 rectangular tube of the outer shell is the frame, and the A3 steel plate is the welded surface of the sealing plate, which is welded to the 22-channel furnace door column for reinforcement. The combustion tunnel support in the furnace is an 80×40 rectangular tube, and 3mmA3 plate is laid on it.

The thermal insulation material of the furnace body is Grade A compressed glass fiber silicate wool. The thickness of the insulation layer is 220mm, and the thickness of the insulation layer is strictly based on 200 kilograms of wool per cubic meter. During heating, the temperature of the outer panel is not higher than that of the air within 10 degrees.

The heat insulation material of the furnace bottom is made of Grade A compressed glass fiber silicate wool, and the insulation layer thickness is 120mm. The inner chamber panel is 2mmcr13 stainless steel plate and the bottom frame are welded.

The furnace door is made of four 16-channel steel, the end face is sealed with A3S plate, the inside is the up-and-down movement space of the counterweight, and the top cross beam is made of 12-channel steel

Functional description

Low temperature aging, high temperature annealing

The aging furnace is used for aging treatment of profiles. The furnace adopts a large air volume circulating fan installed at the top of the furnace to ensure uniform temperature in the furnace. The upper air duct is provided with a heating device, and the air in the furnace heated by the heating device is blown to the workpiece on the lower air duct by the circulating fan, so that the workpiece is heated to the process temperature within the specified time and kept insulated for a period of time, and the temperature difference between the front and the back of the workpiece is close to, and the effect of heat treatment is cooled, so as to achieve the effect of heat treatment.

Air circulation system

Low temperature aging, high temperature annealing

The aging furnace is used for aging treatment of profiles. The furnace adopts a large air volume circulating fan installed at the top of the furnace to ensure uniform temperature in the furnace. The upper air duct is provided with a heating device, and the air in the furnace heated by the heating device is blown to the workpiece on the lower air duct by the circulating fan, so that the workpiece is heated to the process temperature within the specified time and kept insulated for a period of time, and the temperature difference between the front and the back of the workpiece is close to, and the effect of heat treatment is cooled, so as to achieve the effect of heat treatment.

This system is the key to ensure the heating speed and temperature uniformity of the product to meet the technological requirements. In order to strengthen heat exchange and ensure the product quality, a large air volume circulating fan is installed on the top of the furnace. When the furnace adopts this system, the temperature uniformity of the furnace air temperature is plus or minus 3 ℃ during heat preservation.

Flow guide device

The device is installed at both ends of the air duct in the furnace, and the main material is 2MM steel plate, which is processed into a semicircular shape, reasonably distributed according to the shape of the material frame, guiding the direction of the air flow, and improving the air flow distribution. The device makes the air volume at each point of the cross section uniform when the hot air circulates in the furnace, thus ensuring the temperature difference requirement in the furnace, and improving the heat exchange effect between the profile and the furnace gas

The circulation path of the gas in the furnace is as follows:

Combustion gun → ring patrol fan → guide plate → air ducts on both sides of the fan → guide mechanisms on both sides of the furnace (the air flow into the furnace is distributed through the guide plate) → furnace (enters the furnace through the guide plates on both sides of the furnace) → Heat exchange with profiles → guide mechanisms on both sides of the furnace → ring patrol fan

Heating system

The furnace adopts a liquefied petroleum gas burner to heat the air in the furnace for circulation. This heating method has high thermal efficiency, energy saving and environmental protection, discharges the exhaust gas through the chimney, has remarkable energy saving effect, and the accuracy required for temperature control is very reliable.